PLEASE NOTE: If you had an account with the previous forum, it has been ported to the new Genetry website!

You will need to reset the password to access the new forum. Click Log In → Forgot Password → enter your username or forum email address → click Email Reset Link.

I have 8 of these BYD 3.2v 250ah cells.

They came with studs on the ends, and you can't tighten them tight, however, one of the cells, the studs on both ends just well fell off, and from what somebody told me at a welding shop that the ends look like its lead terminals.

So right now I am stuck with no idea on how to fix the cell so I can use it wit the other 7 cells for my 24v system.

Anybody has any Idea, since from what I told the EPA cracked down on allowing folks to even mess with lead welding and so forth.

I thought of putting it under my drill pres and drill a small 3mm hole and then tap it and plut a stud that way, but not sure if thats even the right way of going.

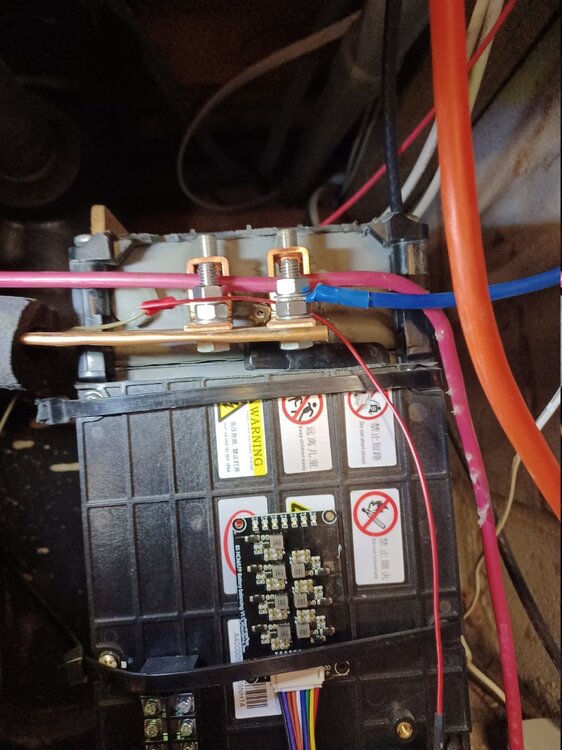

Well, I figured out a way to use the cell, just use a wratchet strap, and a lug on a end of the wire, with it on the terminal with the strap over that holding it in place then just give it a click or two to make it where its not going to budge, and call it good. seems to work. Not planning on pulling a full 100amps off of it anyhow. So right now, got all 8 cells all hooked up as one big 3.2v family, 2000ah, yeah boy, I bet that thing would light up a light like the sun if it got shorted lol. . . Top balancing got a 10a set at 3.65v on it, will leave it hooked up until I get a new BMS 24v, I got to find one that got the wires already solder on the dang thing I got one here, but its not got the wires on it. and I hate trying to solder wires on a pcb,

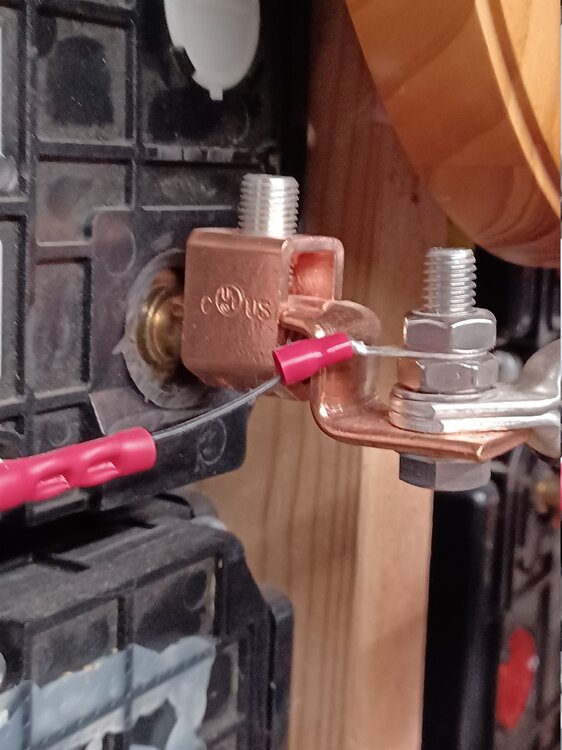

I have the BYD modules that I think you are talking about. When I received them, two had posts that just came off. I ground off enough of the plastic insulator around the existing terminal sticking out of the cell to attach a setscrew type copper lug bought from home depot. Then attached wires/busbars to that. Used those same lugs for the regular round posts for better connections. Will attach some pics but don't know if that will help you....

Okay, well I'm blind of course, do you mean below the lead post that is sticking out, the look like melted rounded around the side of the post is plastic? does the lead post un screw then?

Can you find the copper lug your talking about on amazon by chance? cause there is plenty of post sticking out pass the plastic, I don't see why you would need to grin the plastic if its a set screw, did you just srew the lug directly in the center of the lead post?